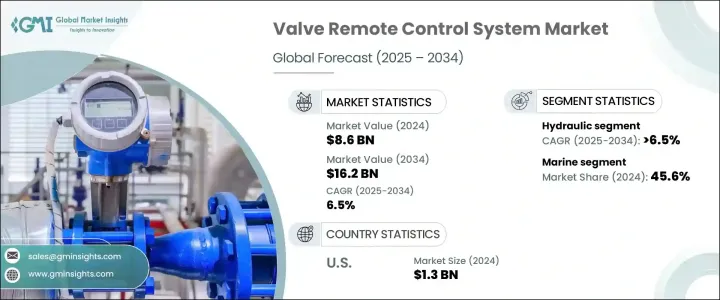

세계의 밸브 원격 제어 시스템 시장은 2024년 86억 달러로 평가되었고, 자동화 기술의 채용이 증가하고, 긴급 누출 방지 및 안전 준수에 있어서 원격 시스템의 중요한 역할에 의해 CAGR 6.5%로 성장하고, 2034년까지 162억 달러에 이를 것으로 예측되고 있습니다.

이러한 시스템은 파이프라인 내의 유체 흐름을 차단하고 대응 시간을 대폭 단축하며 환경 및 운영상의 손해 위험을 최소화하는 데 중요한 역할을 합니다.

밸브 원격 제어 시스템은 기업이 인프라의 스마트화 및 디지털 전환을 추진하는데 있어서 필수적인 것이 되고 있습니다. 중요한 운영에서보다 빠르고 안전하며 응답성이 높은 시스템을 요구하는 요구가 자동 밸브 기술에 대한 투자를 뒷받침합니다. 인프라의 탄력성에 더 많은 압력을 가하는 동안 원격 밸브 제어는 설득력 있는 솔루션을 제공합니다. 기업은 또한 모듈성, 확장성, 사이버 안전한 연결성을 제공하는 솔루션을 우선하고 있으며, 기존의 기계적 조작에서 스마트하고 적응성이 높은 제어 아키텍처로의 시프트를 시사하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 86억 달러 |

| 예측 금액 | 162억 달러 |

| CAGR | 6.5% |

이 성장에 박차를 가하고 있는 주요 요인은 긴급 차단 밸브의 채용입니다. 긴급 차단 밸브는 오퍼레이터가 몇 초 이내에 문제점을 격리할 수 있게 하고, 누출이나 기타 참사의 가능성을 줄여줍니다. 스마트 밸브 시스템은 안전한 제어 센터로부터의 집중 조작을 가능하게 하기 위해 위험한 원격 환경에서의 자동화를 추진하는 움직임은 시장의 기세를 더욱 가속시키고 있습니다.

공압 밸브 원격 제어 시스템 분야에서도 2024년에는 15억 달러의 매출이 있었습니다. 기계적 단순성, 신뢰성, 적응성으로 다운타임을 삭감하고 시스템의 안전성을 높이고 싶은 시설에 최적인 솔루션이 되고 있습니다.

용도별로 해양 분야가 시장을 선도하고 2024년에는 45.6%의 압도적 점유율을 획득합니다. 자동화하는 능력은 수동 개입을 대폭 삭감하고 실시간 의사결정을 지원하며 선상의 안전성을 높입니다.

미국의 밸브 원격 제어 시스템 시장은 2024년에 13억 달러를 창출해 산업의 업그레이드나 인프라의 근대화를 원동력으로 하는 전국적인 보급의 기세를 반영하고 있습니다. 미국의 산업계는 이러한 시스템을 보다 광범위한 운영 플랫폼에 통합하고 있습니다. 수도 사업과 에너지 생산에서 중공업과 해운에 이르기까지 기업은 안전성 향상, 인건비 절감, 신속한 긴급 대응을 위해 밸브의 원격 조작을 활용하고 있습니다.

Velan, Honeywell International, HAWE Hydraulik, Rotork, Emerson Electric, Flowserve, Valmet, KSB SE, Mowe Marine & Offshore, ATHENA ENGINEERING과 같은 업계의 주요 기업은 첨단 자동화 기술에 많은 투자를 하고 있습니다.그들의 전략에는 모듈식으로 확장 가능한 시스템 설계의 개발, 생산 능력의 증강, 사이버에 강한 통신 프로토콜의 확보, 틈새 밸브 기술 제공업체의 인수에 의한 시장 확대와 제품 제공의 확대 등이 포함됩니다.

The Global Valve Remote Control System Market was valued at USD 8.6 billion in 2024 and is estimated to grow at a CAGR of 6.5% to reach USD 16.2 billion by 2034, driven by the increasing adoption of automation technologies and the critical role of remote systems in emergency leak prevention and safety compliance. These systems play a vital role in shutting down fluid flow in pipelines, drastically reducing response times and minimizing the risk of environmental and operational damage. As industries across the board place growing emphasis on operational efficiency, safety, and regulatory compliance, the demand for robust and intelligent valve control solutions continues to rise.

Valve remote control systems are becoming indispensable as companies push toward smarter infrastructure and digital transformation. Industries such as oil and gas, maritime, water treatment, chemical processing, and utilities are embracing these systems to enhance real-time fluid management and reduce reliance on manual intervention. The need for faster, safer, and more responsive systems in critical operations is propelling investments in automated valve technologies. As extreme weather events, geopolitical tensions, and global energy demand place further pressure on infrastructure resilience, remote valve control offers a compelling solution. In an increasingly data-driven world, the ability to integrate these systems with industrial IoT platforms, SCADA, and AI-based predictive maintenance tools is not just a bonus-it's fast becoming a necessity. Businesses are also prioritizing solutions that offer modularity, scalability, and cyber-secure connectivity, signaling a shift from traditional mechanical operations to smart, adaptive control architectures.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $8.6 Billion |

| Forecast Value | $16.2 Billion |

| CAGR | 6.5% |

A key factor fueling this growth is the adoption of emergency shut-off valves that empower operators to isolate problem areas within seconds, reducing the likelihood of leaks and other catastrophic failures. This technological advantage, paired with increasingly stringent global safety regulations, is prompting widespread infrastructure upgrades across high-risk industries. The drive toward automation in hazardous and remote environments has further accelerated market momentum, as remote valve systems allow centralized operation from safe control centers. In sectors like marine shipping, petrochemical refining, and wastewater treatment-where precision and speed are non-negotiable-these systems are proving to be mission-critical assets.

The pneumatic valve remote control systems segment alone generated USD 1.5 billion in 2024. These systems are especially popular in industries where electrical components may pose safety risks or where operations must continue without reliance on constant power sources. Operating on compressed air, pneumatic systems offer fast, dependable actuation even in explosive or corrosive settings. Their mechanical simplicity, reliability, and adaptability make them a go-to solution for facilities looking to reduce downtime and enhance system safety. From oil and gas facilities to industrial manufacturing plants and marine environments, pneumatic systems provide a durable option in high-risk scenarios.

Within the application landscape, the marine sector leads the market, capturing a dominant 45.6% share in 2024. Ships, submarines, and offshore platforms all require precise management of fuel, ballast, and wastewater systems, making centralized valve control not only advantageous but essential. The ability to automate valve operations significantly reduces manual intervention, supports real-time decision-making, and enhances onboard safety. As global maritime operators push for more intelligent vessel operations, the demand for valve remote control systems continues to rise, especially in retrofitting initiatives aimed at modernizing older fleets.

The U.S. Valve Remote Control System Market generated USD 1.3 billion in 2024, reflecting strong nationwide adoption driven by industrial upgrades and infrastructure modernization. With a growing emphasis on predictive maintenance, digital monitoring, and smart automation, U.S. industries are integrating these systems into broader operational platforms. From water utilities and energy production to heavy industry and shipping, companies are leveraging remote valve actuation to improve safety, reduce labor costs, and ensure faster emergency response.

Key industry players-including Velan, Honeywell International, HAWE Hydraulik, Rotork, Emerson Electric, Flowserve, Valmet, KSB SE, Mowe Marine & Offshore, and ATHENA ENGINEERING-are investing heavily in advanced automation technologies. Their strategies include developing modular and scalable system designs, boosting production capacity, securing cyber-resilient communication protocols, and acquiring niche valve technology providers to expand their market reach and product offerings.